Square wave test - caution: (I should have said) if fed through the preamp the EQ will have a profound effect on waveshape, therefore this test is really only meaningful when applied to the power amp alone (e.g. via Fx Return).

My first thought also.

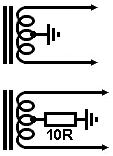

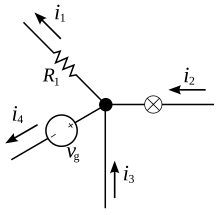

Your enemy;

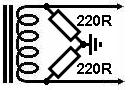

The lower trace is showing bursts of high frequency parasitic oscillation on a signal. Unlike straight supersonic oscillation parasitic oscillations only occur under certain circuit conditions of drive and load, the circuit is said to be only conditionally stable, and this is the implication of the Acoustic caution mentioned by gbono above. Ideally all amplifiers should be UN-conditionally stable under all load and signal conditions.

Using a square rather than sine wave is poking a stick down its hole, a serious provocation for an instability to show itself. The sharp edge of the square wave is an electronic version of giving it a whack on the case. If anything is going to ping, ring, or burst into HF oscillation, that's when it is going to be "shocked" into doing it.

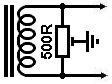

I've encountered the very occasional roasted Zobel, but apart from obvious stuff like the cap shorted, it's hard to tell what conditions may have caused the failure since they always seem to be situational, unreported to me (e.g. using a curly cord for the speaker), and no other fault can later be found in the amp. I've had amps in for other repairs where the Zobel must have been burned out years before (e.g. fluff accumulating on the burnt resistor), the cause lost in the mists of time, and perhaps multiple ownership.

Most times a bit of detective work will develop a reasonable explanation for a fault, (e.g. one of the speaker leads has an intermittent short), but there are also a small percentage of repairs where is is not obvious from the equipment and there is a lack of other information.

{I'm reminded of a multi-headphone amp from a studio with one output seriously fried. The only thing I could say for sure is that there wasn't enough power available within the unit to cause that much damage, so the power had apparently come in via the headphone socket. I can only guess that somebody accidentally plugged an amp speaker lead into the headphone output (both 6.5mm) and gave their amp a thrash. It certainly isn't the first time I've seen damage from that mistake. For a conscientious repairer a guess, even a good one, isn't very satisfactory because it's nice to be certain, but without somebody putting their hand up it had to remain a mystery.}

Quote from: J M Fahey* wobbly and double-vision sinewave?: the sinewave is perfect, you are having a sync problem in your scope.

My first thought also.

Your enemy;

The lower trace is showing bursts of high frequency parasitic oscillation on a signal. Unlike straight supersonic oscillation parasitic oscillations only occur under certain circuit conditions of drive and load, the circuit is said to be only conditionally stable, and this is the implication of the Acoustic caution mentioned by gbono above. Ideally all amplifiers should be UN-conditionally stable under all load and signal conditions.

Using a square rather than sine wave is poking a stick down its hole, a serious provocation for an instability to show itself. The sharp edge of the square wave is an electronic version of giving it a whack on the case. If anything is going to ping, ring, or burst into HF oscillation, that's when it is going to be "shocked" into doing it.

I've encountered the very occasional roasted Zobel, but apart from obvious stuff like the cap shorted, it's hard to tell what conditions may have caused the failure since they always seem to be situational, unreported to me (e.g. using a curly cord for the speaker), and no other fault can later be found in the amp. I've had amps in for other repairs where the Zobel must have been burned out years before (e.g. fluff accumulating on the burnt resistor), the cause lost in the mists of time, and perhaps multiple ownership.

Most times a bit of detective work will develop a reasonable explanation for a fault, (e.g. one of the speaker leads has an intermittent short), but there are also a small percentage of repairs where is is not obvious from the equipment and there is a lack of other information.

{I'm reminded of a multi-headphone amp from a studio with one output seriously fried. The only thing I could say for sure is that there wasn't enough power available within the unit to cause that much damage, so the power had apparently come in via the headphone socket. I can only guess that somebody accidentally plugged an amp speaker lead into the headphone output (both 6.5mm) and gave their amp a thrash. It certainly isn't the first time I've seen damage from that mistake. For a conscientious repairer a guess, even a good one, isn't very satisfactory because it's nice to be certain, but without somebody putting their hand up it had to remain a mystery.}

}

}

*t + (148)

*t + (148)